If you’re exploring the top hydrogen fuel cell stacks of 2025, I’ve found some great options around 500W that deliver high performance, durability, and safety. These stacks feature advanced designs like water cooling and low platinum use, making them efficient and long-lasting. They’re perfect for various applications, from educational models to research. Stick around, and you’ll discover detailed reviews to help you choose the best power source for your needs.

Key Takeaways

- Top-rated 2025 hydrogen fuel cell stacks achieve 0.58-1.4 W/cm² power density with durability over 20,000 cycles.

- Water-cooled designs ensure stable performance and longevity in high-power 500W fuel cell stacks.

- Low platinum loading (0.3-0.45 mg) reduces costs while maintaining high efficiency and durability.

- Compatibility with system size, voltage, and cooling requirements is crucial for optimal 500W fuel cell integration.

- Enhanced safety, high performance standards, and material quality ensure reliable operation of top fuel cell stacks in 2025.

Horizon Fuel Cell Technologies Solar Hydrogen Education Kit

If you’re looking for an educational hydrogen fuel cell kit that makes learning about renewable energy engaging and accessible, the Horizon Fuel Cell Technologies Solar Hydrogen Education Kit is an excellent choice. I love how it combines hands-on experiments with real-world science, allowing students to produce renewable hydrogen from sunlight and water. The kit includes a fuel cell, a small electric motor, and an experiment manual that guides you through the process. It’s perfect for inspiring curiosity about sustainable energy, showcasing the potential of solar power and hydrogen fuel cells. Plus, it’s designed to make complex concepts fun and easy to understand.

Best For: educators, students, and science enthusiasts interested in hands-on renewable energy experiments and learning about hydrogen fuel cells.

Pros:

- Engages learners with interactive, hands-on experiments.

- Demonstrates real-world applications of solar energy and hydrogen production.

- Includes comprehensive guides to facilitate easy understanding of complex concepts.

Cons:

- May require additional safety precautions when working with water and hydrogen-related components.

- Limited to basic experiments, possibly requiring supplementary materials for advanced learning.

- The setup might be less suitable for very young children due to small parts and technical content.

Hydrogen Fuel Cell Electric Vehicle Model

The Hydrogen Fuel Cell Electric Vehicle Model stands out as an excellent educational tool for students and enthusiasts interested in clean energy technology. It includes a car model, hydrogen cylinder, fuel cell, filling syringe, and spare plug—citric acid isn’t included. The model demonstrates hydrogen generation using zinc particles and citric acid, with hot water at 80°C necessary for *ideal* hydrogen production. During operation, hydrogen reacts with air within the fuel cell to generate electricity, powering the vehicle. Proper venting ensures pure hydrogen and air mix, *crucial* for efficient power. This hands-on setup effectively illustrates clean energy principles and fuel cell operation in a clear, engaging way.

Best For: students, educators, and enthusiasts interested in learning about clean energy technology and hydrogen fuel cell operation.

Pros:

- Provides a comprehensive and hands-on educational experience in fuel cell technology and hydrogen generation

- Demonstrates clean energy principles in an engaging and visual manner

- Includes all necessary components for classroom demonstrations, enhancing practical understanding

Cons:

- Citric acid is not included, requiring additional purchase for setup

- Requires hot water at 80°C for optimal hydrogen production, which may need careful handling

- The model may need supervision to ensure proper venting and operation during experiments

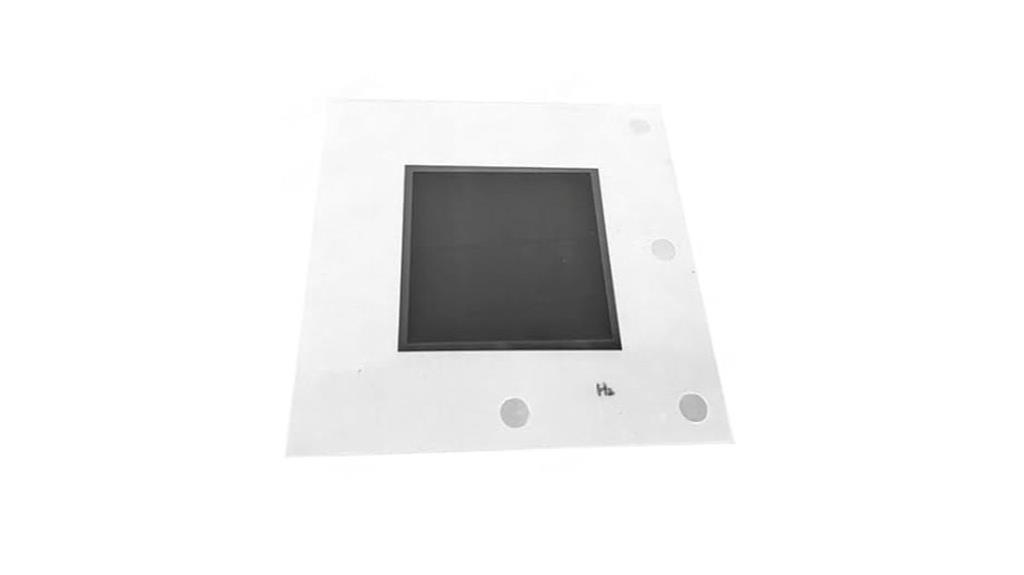

Water-Cooled Fuel Cell MEA Sheet (50x50mm)

Looking for a fuel cell solution that combines high efficiency with reliable temperature management? The Water-Cooled Fuel Cell MEA Sheet (50x50mm) delivers just that. It features a high power density of 1.3-1.4W/cm² at 0.65V, optimized for hydrogen systems. Its water-cooled design guarantees consistent temperature control, boosting performance and longevity. With less than 5% power attenuation over 20,000 cycles, it’s built for demanding applications. Plus, its low platinum loading of 0.3-0.35mg makes it cost-effective and environmentally friendly. Customizable to specific needs, this MEA sheet offers a reliable, high-performance solution for advanced fuel cell stacks.

Best For: researchers and engineers seeking a high-performance, durable, and cost-effective hydrogen fuel cell solution with efficient temperature management.

Pros:

- High power density of 1.3-1.4W/cm² at 0.65V for optimal energy output

- Water-cooled design ensures reliable temperature control and enhanced longevity

- Low platinum loading (0.3-0.35mg) reduces costs and environmental impact

Cons:

- Customization options may require additional development time

- Limited to specific dimensions (50x50mm), which may not suit all applications

- Potential complexity in integrating water cooling systems into existing setups

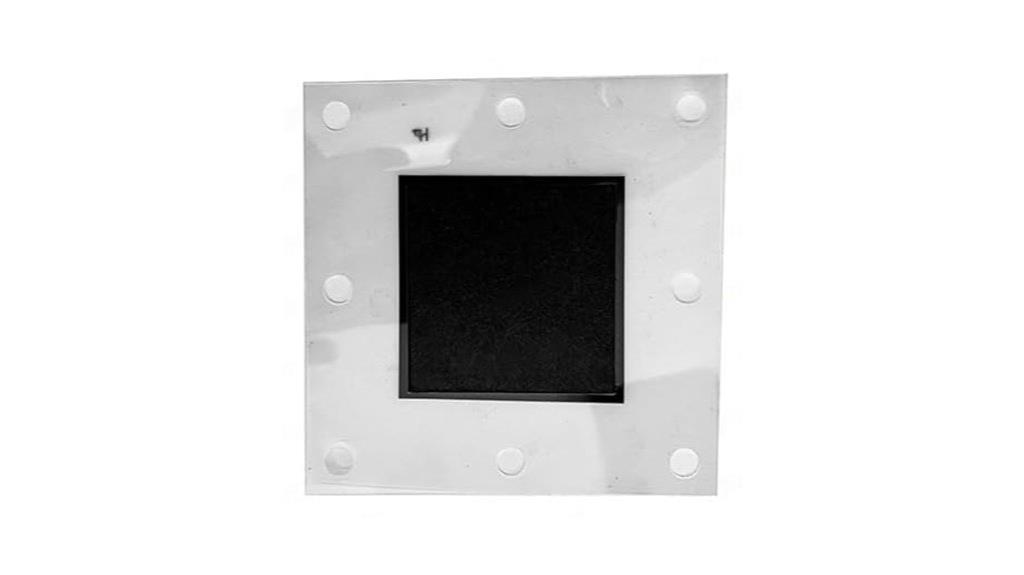

Stack Membrane Electrode Sheet for Hydrogen Fuel Cells

For researchers and developers seeking reliable, high-performance components, the Stack Membrane Electrode Sheet for Hydrogen Fuel Cells stands out as an ideal choice. This customizable MEA measures 60×60 mm and delivers impressive power density of 0.58-0.6W/cm² at 2A/cm² and 0.65V. It offers long-lasting performance with less than 5% power loss over 5,000 cycles, ensuring durability. Its low platinum load of 0.4-0.45mg makes it cost-effective without sacrificing efficiency. Designed for research and development, this membrane electrode sheet supports diverse applications and fosters innovation in hydrogen energy solutions.

Best For: researchers and developers seeking reliable, high-performance components for hydrogen fuel cell applications.

Pros:

- High power density of 0.58-0.6W/cm² at 2A/cm² and 0.65V, ensuring strong energy output

- Long-lasting performance with less than 5% power attenuation over 5000 cycles

- Cost-effective due to low platinum loading of 0.4-0.45mg without compromising efficiency

Cons:

- Customization options may lead to longer lead times for specific project needs

- Limited size options (60×60 mm) may require additional scaling for larger applications

- Potential complexity in integrating with existing fuel cell systems requiring specialized knowledge

Proton Exchange Membrane Fuel Cell (2.0×2.0 inch)

If you’re seeking an educational hydrogen fuel cell ideal for high school labs, the Proton Exchange Membrane Fuel Cell (2.0×2.0 inch) stands out due to its compact size and user-friendly design. Measuring just 2.0×2.0 inches, it’s perfect for demonstrations and experiments. It converts hydrogen into clean electrical energy using proton exchange membranes and carbon paper, with no internal battery required. Easy to operate and practical, this cell helps students grasp renewable energy concepts. However, some reports mention non-functionality, so troubleshooting or additional testing might be necessary to ensure maximum performance.

Best For: high school science teachers and students seeking an easy-to-use, educational hydrogen fuel cell for demonstrations and experiments.

Pros:

- Compact size (2.0×2.0 inches) ideal for classroom use and demonstrations

- Uses proton exchange membranes and carbon paper for clean energy conversion without internal batteries

- Easy to operate, making it accessible for students learning about renewable energy

Cons:

- Some reports indicate the unit may be non-functional, requiring troubleshooting

- Limited technical details on membrane type and performance specifications

- May necessitate additional testing to ensure consistent operation

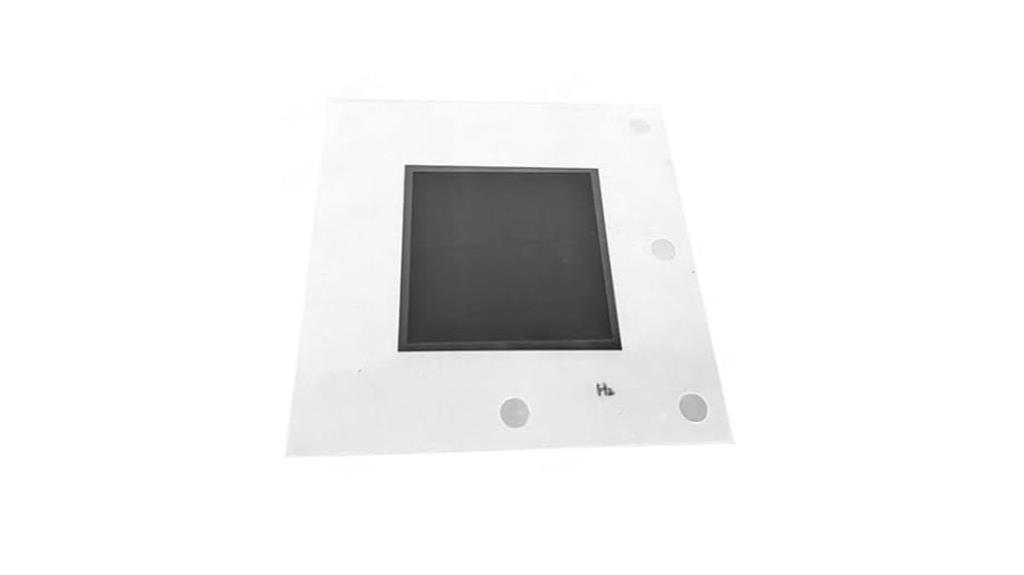

Water-Cooled Stack Membrane Electrode Sheet for Hydrogen Fuel Cells

The Water-Cooled Stack Membrane Electrode Sheet stands out as an ideal choice for advanced hydrogen fuel cell systems that demand high performance and long-term durability. It delivers a power density of 1.3–1.4 W/cm² at 2 A/cm² and 0.65 V, ensuring efficient energy output. Its design supports up to 20,000 cycles with less than 5% power loss, highlighting its longevity. Featuring low platinum loading of 0.3–0.35 mg, it keeps material costs low without sacrificing reliability. The water-cooled architecture effectively manages heat, enabling stable operation over extended cycles, making it perfect for sustainable, high-demand fuel cell applications.

Best For: Advanced hydrogen fuel cell system developers seeking high performance, durability, and cost-effective energy solutions.

Pros:

- High power density of 1.3–1.4 W/cm² at 2 A/cm² and 0.65 V ensures efficient energy output

- Supports up to 20,000 cycles with minimal power attenuation for long-term durability

- Low platinum loading (0.3–0.35 mg) reduces material costs while maintaining reliability

Cons:

- Customization options may require additional development time and costs

- Water-cooled architecture needs proper thermal management infrastructure

- Performance may vary based on specific application conditions and operational parameters

Hydrogen Fuel Cell Electric Car Model for Teaching and Demonstration

This hydrogen fuel cell electric car model is an ideal educational tool for students and instructors aiming to understand clean energy technology firsthand. It demonstrates how hydrogen and oxygen produce electricity to power vehicles, emphasizing sustainable transportation. The model includes high-tech instruments showing hydrogen synthesis from zinc particles and citric acid, with hot water at 80°C ensuring efficient hydrogen production. Proper safety procedures, like venting and re-sealing gas lines, are essential for effective operation. This hands-on setup helps learners grasp fuel cell principles, hydrogen generation, and eco-friendly vehicle technology, making complex concepts accessible and engaging.

Best For: educators, students, and researchers interested in hands-on learning about clean energy and hydrogen fuel cell technology.

Pros:

- Provides an interactive and visual demonstration of hydrogen production and fuel cell operation.

- Enhances understanding of sustainable transportation and eco-friendly vehicle technology.

- Incorporates high-tech instruments for accurate and engaging teaching experiences.

Cons:

- Requires strict safety procedures, such as venting and re-sealing gas lines, to prevent hazards.

- Necessitates maintaining specific experimental conditions, like water at 80°C, for optimal performance.

- May involve costs related to high-tech equipment and consumables like zinc particles and citric acid.

Hydrogen Gas Tablets and Fuel Cell Generator for Laboratory Use

Students and educators seeking safe, reliable tools to explore hydrogen fuel cell technology will find hydrogen gas tablets and fuel cell generators ideal for laboratory use. These devices serve as excellent educational tools, allowing hands-on experiments with renewable energy concepts. Engineered for safety and efficiency, they produce controlled hydrogen gas and utilize advanced proton exchange membrane technology for consistent performance. Built with durable materials, they support long-term classroom use. These generators help students grasp complex scientific principles and real-world applications of hydrogen energy, making them a valuable addition to any high school lab focused on STEM learning and environmental science.

Best For: high school educators and students seeking a safe, reliable, and educational introduction to hydrogen fuel cell technology and renewable energy concepts.

Pros:

- Facilitates hands-on learning and experiments in STEM and environmental science.

- Engineered for safety with controlled hydrogen gas production and advanced technology.

- Durable construction suitable for long-term classroom use and repeated demonstrations.

Cons:

- May require proper training for safe handling of hydrogen gas and fuel cell components.

- Limited to educational settings; not designed for industrial or large-scale applications.

- Initial setup and maintenance might be complex for some users unfamiliar with fuel cell technology.

Hydrogen Fuel Cell Power Generation Module

If you’re seeking an educational tool that combines portability with ease of demonstration, the Hydrogen Fuel Cell Power Generation Module is an excellent choice. It’s compact, measuring just 72x65x30mm, and weighs around 60 grams, making it perfect for hands-on learning. This small-scale hydrogen fuel reactor delivers an open circuit voltage over 0.9V and a current range up to 0.6A, suitable for simple electrical projects. While its size is impressive, users should be cautious and seek guidance, as it lacks detailed instructions. Overall, it offers a visually appealing and practical way to explore hydrogen fuel cell technology in educational settings.

Best For: educators and students seeking a portable, hands-on demonstration tool to explore hydrogen fuel cell technology in a classroom or laboratory setting.

Pros:

- Compact and lightweight design enhances portability and ease of use.

- Suitable for small electrical projects and educational demonstrations.

- Visually appealing size helps engage learners and simplify understanding.

Cons:

- Lacks detailed instructions, which may cause uncertainty in operation.

- Limited to low current output (up to 0.6A), restricting more complex applications.

- No additional accessories or guidance included, requiring users to seek supplementary information.

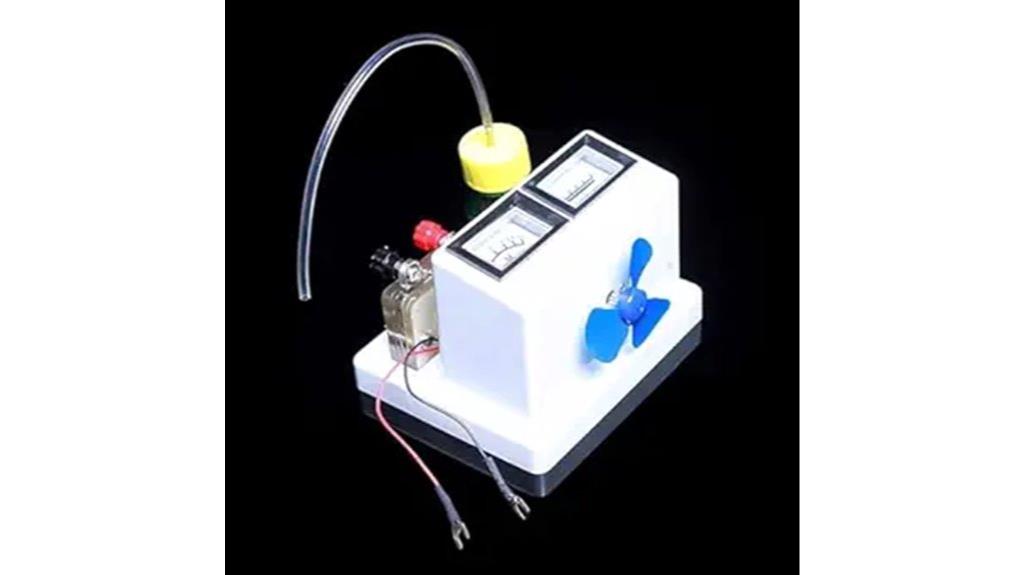

VERIMP Reversible Hydrogen Fuel Cell and Electrolyzer Physics and Electricity Experiment Kit

The VERIMP Reversible Hydrogen Fuel Cell and Electrolyzer Physics Experiment Kit stands out as an ideal choice for educators and enthusiasts seeking a hands-on tool to demonstrate the core principles of hydrogen fuel cells and electrolysis. It’s lightweight, weighing around 2 kg, and includes a PEM electrolyzer, motor, ammeter, and voltmeter to measure current and voltage during operation. The system effectively shows how chemical energy converts into electrical energy, producing hydrogen through electrolysis and generating power from hydrogen fuel. Its straightforward setup, safety features, and detailed instructions make it perfect for educational demonstrations of electrochemical processes.

Best For: educators, students, and hydrogen energy enthusiasts seeking an interactive, educational tool to demonstrate the principles of hydrogen fuel cells and electrolysis.

Pros:

- Lightweight and portable, making it easy to set up and transport for demonstrations.

- Complete with essential measurement instruments like ammeter and voltmeter for real-time data collection.

- Supports hands-on learning of electrochemical energy conversion with clear safety instructions and detailed guidance.

Cons:

- Requires careful handling of liquids and proper polarity connections to avoid damage.

- Disassembly of the PEM fuel cell is prohibited, which may limit maintenance options.

- Limited to basic educational demonstrations; not suitable for advanced research or industrial applications.

Hydrogen Fuel Cell Regeneration Module

Designed for educational and experimental purposes, the Hydrogen Fuel Cell Regeneration Module stands out with its clear demonstration of reversible battery functions. It features electrolytic and power generation areas measuring 25×25mm, with electrolytic voltages between 1.5V and 3.0V, and generation voltages from 0.5V to 0.9V. Users can electrolyze water to produce hydrogen and oxygen, then switch to generate electricity by connecting the appropriate outlets and gas collection devices. The module allows hands-on learning of hydrogen-oxygen fuel cell processes, making it an excellent tool to visualize the reversible nature of these energy systems in a controlled environment.

Best For: educators, students, and researchers interested in hands-on learning about hydrogen fuel cells and electrolysis processes.

Pros:

- Provides a clear visual demonstration of reversible hydrogen-oxygen fuel cell functions.

- Compact size (25×25mm) suitable for classroom or laboratory experiments.

- Supports both electrolysis and power generation, enhancing educational versatility.

Cons:

- Production batches may vary in color due to random shipment, potentially affecting uniformity.

- Requires proper setup and handling of gases to ensure safety during operation.

- Limited voltage and gas production rates may restrict large-scale demonstration or experimentation.

Hydrogen Fuel Cell Generation Module Science Kit

For educators and students exploring renewable energy concepts, the Hydrogen Fuel Cell Generation Module Science Kit offers an interactive and all-encompassing way to understand hydrogen fuel cell principles. This kit features a thorough structure, including a PEM fuel cell, hydrogen production bottle, ammeter, voltmeter, and motor with wind blades, enabling hands-on experiments. It demonstrates how chemical energy from hydrogen and oxygen converts into electrical energy without pollution. Operating at voltages between 0.3V and 0.6V, it produces 15MW to 30MW of power, making it ideal for educational demonstrations and experiments. Customer support is responsive, and additional details are readily available for educators and students alike.

Best For: educators and students seeking an interactive, comprehensive kit to understand hydrogen fuel cell principles and renewable energy concepts.

Pros:

- Provides hands-on experiments illustrating hydrogen fuel cell operation and renewable energy technology.

- Includes essential components such as PEM fuel cell, hydrogen production bottle, ammeter, voltmeter, and motor with wind blades for versatile demonstrations.

- Facilitates educational demonstrations with safe, pollution-free energy conversion at practical voltage and power ranges.

Cons:

- Operating voltage (0.3V to 0.6V) and power output (15MW to 30MW) may require additional scaling or integration for certain advanced experiments.

- The kit’s structural components are primarily plastic, which may limit durability for frequent or intense use.

- Requires some basic understanding of electrochemical principles, possibly necessitating supplementary instructional support for complete comprehension.

Factors to Consider When Choosing a Hydrogen Fuel Cell Stack 500W

When selecting a 500W hydrogen fuel cell stack, I consider factors like power output efficiency, durability, and maintenance costs to guarantee long-term performance. Compatibility, size, and heat management also play vital roles in fitting the system to my needs. By carefully evaluating these points, I can choose a reliable and efficient fuel cell for my application.

Power Output Efficiency

Power output efficiency in a 500W hydrogen fuel cell stack hinges on several critical factors. First, the maximum power density, measured in W/cm², indicates how effectively the stack converts fuel into electricity. Achieving high efficiency relies on an ideal membrane electrode assembly (MEA) design, with low platinum loading and efficient water cooling to regulate temperature. Consistency over many cycles, typically between 5,000 to 20,000, is essential to maintain stable performance. Proper gas management—ensuring pure hydrogen and oxygen supply while minimizing leaks—also plays a crucial role. Additionally, operating conditions like temperature, pressure, and humidity substantially influence efficiency, with water-cooled stacks often providing more stable and reliable power output. These factors collectively determine how well a stack performs at its rated power.

Durability and Longevity

Durability and longevity are essential factors to contemplate when selecting a 500W hydrogen fuel cell stack, as they directly influence long-term performance and cost-effectiveness. A dependable stack should sustain less than 5% power attenuation over at least 20,000 cycles, ensuring consistent output over time. The materials in the membrane electrode assembly (MEA) play a critical role; low platinum loading (0.3-0.45mg) can markedly enhance durability without sacrificing efficiency. Water-cooling systems help maintain ideal operating temperatures, reducing thermal stress and extending component lifespan. Proper sealing and high-quality construction prevent contamination and degradation, which are indispensable for sustained operation. Models that achieve reliable performance beyond 20,000 cycles demonstrate excellent design and robust build quality, making them excellent choices for long-term use.

Cost and Maintenance

Choosing a hydrogen fuel cell stack involves balancing initial costs with ongoing maintenance expenses. The price largely depends on platinum loading; lower platinum content, around 0.3-0.45mg, helps reduce costs without sacrificing too much performance. Maintenance includes regular checks of the water cooling system and cleaning electrodes to prevent performance drops. Durability, like achieving over 20,000 cycles with minimal power loss, can lower long-term costs by reducing replacements. Proper handling and sealing of components such as membrane electrode assemblies (MEAs) are crucial to prevent leaks and avoid repairs. Routine system monitoring and timely part replacements also extend the lifespan and maintain efficiency. While initial investment is important, considering these maintenance factors can save money and ensure reliable operation over time.

Compatibility and Size

When selecting a 500W hydrogen fuel cell stack, it’s vital to verify that its size and dimensions fit seamlessly into your system. Making certain of compatibility helps avoid costly modifications and simplifies installation. Check that the stack’s voltage and current ratings align with your power needs and other components, preventing performance issues. Consider the physical size to confirm it suits your application, whether portable or stationary. Don’t forget to examine cooling specifications; proper thermal management is essential, and the size of cooling systems must fit within your design constraints. In the end, confirm that the stack’s dimensions allow for easy installation, maintenance, and connection without requiring extensive adjustments. Proper sizing and compatibility ensure reliable operation and smooth integration into your setup.

Cooling and Heat Management

Proper cooling and heat management are key to ensuring your 500W hydrogen fuel cell stack operates safely and efficiently. Effective cooling methods, like water-cooled or air-cooled designs, are essential for maintaining ideal temperatures and preventing overheating. Water-cooled stacks typically reach higher power densities (1.3-1.4 W/cm²) and support longer cycle lives—up to 20,000 cycles—thanks to superior heat removal. Maintaining a stable temperature around 60-80°C boosts efficiency and prevents performance drops caused by excessive heat. Good heat dissipation design also minimizes risks of thermal runaway, ensuring safe, reliable operation during continuous use. Prioritizing effective heat management not only improves performance but also extends the lifespan of your fuel cell stack, making it a critical factor when choosing the right system.

Material Quality Standards

High-quality materials are vital for guaranteeing your 500W hydrogen fuel cell stack performs reliably and lasts over time. I look for components made from high-purity materials to guarantee efficient electrochemical reactions and durability. Conductive parts, like membrane electrode assemblies (MEAs), should have low internal resistance and high-quality platinum loading—around 0.3-0.45 mg—to optimize performance. Structural components must meet durability standards, capable of withstanding over 20,000 cycles with less than 5% power loss. For water-cooled designs, materials need to resist corrosion and thermal stress to maintain consistent temperature management. Additionally, compliance with safety and environmental standards is vital, ensuring that materials don’t emit harmful substances and support sustainable operation. These standards help guarantee longevity, safety, and peak efficiency in your fuel cell stack.

Frequently Asked Questions

How Does Temperature Affect Hydrogen Fuel Cell Performance?

Temperature critically impacts hydrogen fuel cell performance. When it’s too cold, I notice reduced efficiency because the reactions slow down, and water may freeze, causing damage. In hot weather, I see performance decline due to overheating, leading to potential failure or reduced lifespan. Maintaining an ideal temperature range is essential for consistent operation. That’s why many systems include cooling or heating mechanisms to keep the fuel cell working at its best.

What Safety Precautions Are Essential for Handling Hydrogen Fuel Cells?

Handling hydrogen fuel cells is like walking a tightrope; safety is vital. I always wear protective gear, guarantee proper ventilation, and check for leaks regularly. Using certified equipment and following manufacturer guidelines keeps me safe. I also store hydrogen away from heat and sparks, much like safeguarding a precious treasure. Staying vigilant and informed helps me prevent accidents and keeps the process safe and efficient.

Can These Fuel Cells Operate Efficiently in Extreme Weather Conditions?

Yes, these fuel cells can operate efficiently in extreme weather conditions if they’re properly designed and protected. I guarantee that they’re insulated against cold, and I use moisture barriers in humid environments. Proper ventilation and temperature control are vital to maintain performance. With the right precautions, I’ve found hydrogen fuel cells to be reliable even in challenging weather, making them versatile for various applications.

How Do Maintenance Requirements Vary Among Different Fuel Cell Stacks?

Maintenance needs vary quite a bit among fuel cell stacks. I’ve found that simpler designs, like some 500W models, require minimal upkeep—mainly regular checks and occasional cleaning. More complex stacks with integrated cooling or advanced components demand scheduled inspections and part replacements. I always recommend following manufacturer guidelines closely to keep your fuel cell running efficiently; neglecting maintenance can lead to unexpected failures and costly repairs.

What Is the Expected Lifespan of a 500W Hydrogen Fuel Cell Stack?

A 500W hydrogen fuel cell stack typically lasts between 3,000 to 5,000 hours of operation, depending on maintenance and usage conditions. I’ve found that regular upkeep, like checking seals and replacing filters, markedly extends its lifespan. Proper handling and avoiding extreme temperatures also help preserve its efficiency. Overall, with diligent maintenance, you can expect your fuel cell to serve reliably for several years.

Conclusion

Choosing the right hydrogen fuel cell stack is like finding the perfect compass for your energy journey. With options like educational kits, vehicle models, and high-performance MEA sheets, there’s a clear path to powering innovation. Remember, the best choice depends on your needs and goals. Immerse yourself in these top picks, and you’ll be steering toward a cleaner, greener future—like a ship guided by the brightest star in the hydrogen sky.