To create folding roof decks for tiny houses, you should focus on using lightweight yet sturdy materials like engineered wood, aluminum, or steel frames. Proper support columns, precise hinge placement, and reinforced attachment points ensure safe, smooth operation. Incorporate well-designed drainage, weatherproof coatings, and safety features like guardrails. Confirming compliance with building codes is essential. If you keep exploring, you’ll discover detailed strategies to develop efficient, safe, and functional fold-down roof deck engineering plans.

Key Takeaways

- Design foldable support hinges using heavy-duty materials like stainless steel for durability and safety during deployment.

- Incorporate removable or foldable support columns aligned with the framing to ensure stability and ease of assembly.

- Use modular fastening systems with quick-release clips and hidden fasteners for tool-free deck removal and maintenance.

- Ensure the roof pitch is at least 2/12 for effective drainage, with waterproof membranes applied to prevent leaks during folding.

- Follow local building codes and safety standards, including guardrails, non-slip surfaces, and emergency egress features in engineering plans.

Structural Framework and Support Column Integration

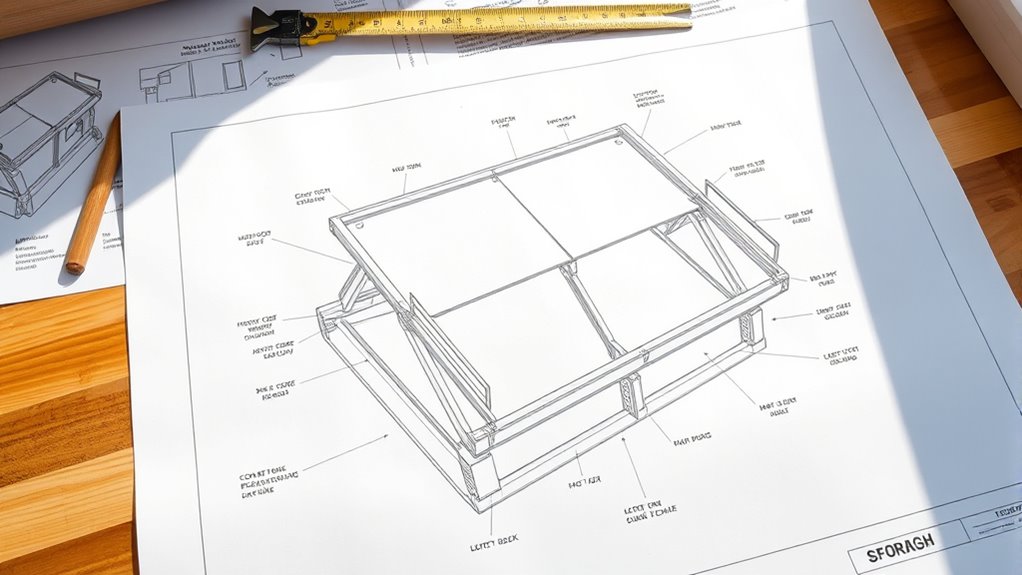

Designing the structural framework for folding roof decks requires selecting lightweight yet strong materials like 1×2, 2×2, and 2×3 lumber to keep the system mobile. These materials provide the necessary strength without adding excess weight, making transportation easier. Use robust hinge systems, such as heavy-duty door hinges, to securely attach foldable sections to the main structure. Incorporate ledger boards as attachment points to distribute loads efficiently and facilitate smooth folding and unfolding. Support columns, like 4×4 posts, should be removable or foldable for portability, resting on heavy-duty concrete blocks for stability during transit. Ensure that support columns align precisely with the framing to minimize stress and prevent deformation. This setup maintains structural integrity while allowing quick assembly and disassembly, essential for a mobile tiny house. Proper load distribution is critical for safety and durability, especially when the deck is in use or during transportation. Additionally, considering regional building codes can help ensure compliance and safety standards are met during design and implementation.

Optimal Roof Pitch and Drainage Solutions

Choosing the right roof pitch is essential for effective drainage and structural efficiency in folding roof decks. A minimum of 2/12 pitch guarantees water flows off properly, preventing pooling and leaks, while maintaining a low profile suitable for tiny houses. Steeper pitches, like 3/12 or more, improve drainage but can increase wind load and complicate folding mechanisms. Shed roof designs with single slopes simplify deck mounting and maximize usable space without complex framing. Incorporating gutters or drainage channels along the lower edge directs runoff away from walls and foundations, protecting your structure. Use waterproof membranes underneath the deck surface, and consider sloped decking boards or gaps to facilitate surface water runoff. Proper pitch and drainage help keep your folding roof deck durable, functional, and weather-resistant. Proper roof pitch also aids in reducing maintenance needs over time. Ensuring correct roof drainage techniques prevents water accumulation that can cause long-term damage.

Cross Member Placement for Stability and Rigidity

Your cross member placement is key to ensuring a stable, rigid roof deck that can fold easily. Positioning them about 3 inches below the trailer frame top offers support while allowing installation of the subfloor, but going flush with the frame can save weight and improve insulation. Using flush crossmembers is especially beneficial for simplifying construction and reducing overall trailer weight. Choosing the right materials and fasteners will maximize stability, especially when supporting dynamic loads during folding and use, and understanding sound design principles can help in developing effective structural solutions.

Optimal Placement Strategies

Proper placement of cross members is essential for ensuring the stability and rigidity of folding roof decks. You should install them perpendicular to main beams at regular intervals to distribute loads evenly and prevent sagging. Closer spacing, like 12-16 inches for heavy loads, increases support, especially near hinges or high-traffic zones. Be sure to align all cross members precisely for uniform load distribution and to avoid stress points. Reinforce attachment points at folding pivots to withstand repeated cycles. Use the following table as a guide:

| Support Zone | Placement Strategy |

|---|---|

| Main deck spans | Every 18-24 inches, closer if heavy |

| Folding joints | Near hinges, double-check alignment |

| High-traffic areas | Reinforce with continuous cross members |

Additionally, heavy loads require more frequent support to maintain structural integrity over time. Ensuring proper load distribution is crucial for long-term durability and safety of the folding roof deck.

Material and Connection Choices

Selecting the right materials and connection techniques is essential for guaranteeing the stability and rigidity of folding roof decks. For frame components, lightweight yet strong materials like aluminum or steel are ideal, offering durability without excessive weight. Use composite decking or waterproof vinyl for surfaces, combining weather resistance with functionality. When connecting parts, welding provides secure, rigid joints for metal frames, while galvanized or stainless steel hardware prevents corrosion. Concealed fasteners create a clean finish on composite decks, and self-tapping screws simplify attachment to metal frames. Cross member placement is critical; they should be positioned to evenly distribute loads and enhance structural integrity. Matching the material of cross members to the frame ensures uniform strength, and proper span between them boosts overall rigidity and stability. Proper installation techniques, including accurate alignment and secure fastening, are vital to maintain these qualities over time. Additionally, metal framing can be treated or coated to resist corrosion, extending the lifespan of the deck structure. Ensuring correct connection methods not only improves safety but also contributes to the overall longevity of the structure by preventing loosening and degradation.

Material Selection for Lightweight and Durable Construction

Choosing the right materials can make your folding roof deck both lightweight and durable. You’ll want to contemplate options like metal or composite decking for strength and resistance to weather. By selecting coatings that protect against corrosion and moisture, you ensure your deck stays lasting and low-maintenance. Engineered wood options like OSB or treated plywood can also be considered for added stability, but they may require additional protective layers to enhance their weather resistance. Additionally, considering the environmental impact of your material choices can help promote sustainability and eco-friendliness in your tiny house project.

Lightweight Structural Materials

Lightweight structural materials are essential for creating durable, efficient, and easy-to-transport buildings like tiny houses and folding roof decks. Honeycomb wood siding provides stability and insulation without adding weight, while metal roofing panels offer a lightweight, salvageable alternative to traditional materials. Steel framing reduces overall weight while maintaining strength, and lightweight concrete panels maximize space with minimal thickness. Trusscore Wall&CeilingBoard, made from PVC, is moisture-resistant and strong. You can also consider innovative options like Structural Insulated Panels (SIPs) for combined insulation and strength, or aluminum composite panels for impact resistance and ease of installation. Sustainable choices like reclaimed wood, cedar, bamboo, and engineered wood provide eco-friendly, lightweight options. These materials help you build sturdy, transportable structures without sacrificing durability or performance. Lightweight materials reduce transportation costs and ease installation, ensuring the building process remains efficient and cost-effective. Additionally, selecting appropriate fastening methods is crucial to maintain the integrity of the lightweight structure during transportation and use.

Weather-Resistant Coatings

Weather-resistant coatings play a crucial role in protecting lightweight, durable structures from harsh environmental conditions. These coatings, such as GacoFlex and Henry 587 Dura-Brite, offer long-lasting protection that extends the roof’s lifespan. Reflective coatings help reduce energy costs by keeping your tiny house cooler, especially in sunny climates. They’re versatile and can be applied to various roofing materials like metal and asphalt shingles, making them adaptable to different needs. Most coatings are easy to apply with rollers or sprayers, simplifying maintenance and repairs. While some are more costly upfront, they save money over time through lower energy bills and reduced repairs. Elastomeric, silicone, polyurethane, and acrylic coatings each bring unique benefits, ensuring your roof stays weatherproof and efficient. Proper application techniques are essential to maximize the effectiveness and longevity of these coatings. Using weather-resistant coatings effectively can also prevent damage caused by moisture and UV exposure, which are common concerns for lightweight roofing systems.

Hardware and Fastening Techniques for Removability

To guarantee your folding roof deck remains functional and easy to remove, selecting the right hardware and fastening techniques is essential. Use durable materials like stainless steel or aluminum for hardware to prevent corrosion and ensure longevity. Opt for hidden fasteners, such as Eurotec Twin System Holders, to keep the deck surface clean and facilitate removal. Quick-release mechanisms and clips or plugs enable fast, tool-free removal and reinstallation of deck boards. Consider modular systems with aluminum profiles or stainless steel plates for secure, yet accessible fastening. Ensure your chosen hardware supports the maximum load capacity, distributes loads evenly, and is compatible with your decking material. Eurotec profile screws are made from #316 stainless steel, offering exceptional corrosion resistance and durability in marine environments. Incorporating appropriate fastening techniques is crucial for maintaining structural integrity and safety over time. Regular inspections and maintenance are vital to confirm fastener integrity, safety, and compliance with building codes.

Waterproofing and Weatherproofing Strategies

Choosing the right waterproof membrane is essential for your folding roof deck’s durability, and you’ll want to contemplate options like liquid coatings, sheet membranes, or vinyl systems. Proper application of protective coatings and sealants helps prevent damage from weather and foot traffic. Ensuring effective drainage and sealing around edges keeps water away and extends your deck’s lifespan. Regular maintenance and inspections are also crucial to identify and address potential issues early, further protecting your investment.

Waterproof Membrane Selection

How do you select the best waterproof membrane for folding roof decks on tiny houses? First, consider the membrane’s flexibility to handle movement during folding and unfolding. Second, evaluate its durability against UV exposure, foot traffic, and weather conditions. Third, guarantee compatibility with your deck’s substrate, whether wood or masonry.

Here’s what to keep in mind:

- Sheet membranes—made from rubber, plastic, or bituminous materials—are durable and UV resistant but tricky around corners.

- Liquid-applied membranes—flexible, seamless, and easy to repair—are great for cracks and irregular surfaces.

- PVC, TPO, or rubber membranes—offer good waterproofing, UV resistance, and are suitable for low-pitch roofs but need precise installation.

Pick a membrane that balances flexibility, durability, and compatibility for your tiny house’s folding roof.

Protective Coating Applications

Wondering how to effectively protect your tiny house‘s folding roof deck from the elements? Protective coating applications are key. Liquid waterproof membranes create seamless barriers that adapt to irregular surfaces, preventing water intrusion. Waterproofing paints and elastomeric coatings add moisture resistance while enhancing appearance, but require multiple coats for durability. Polyurethane coatings are flexible, ideal for complex shapes and details, offering excellent weather resistance. For flat or expansive roofs, bituminous membranes or torch-applied layers provide robust waterproofing. EPDM rubber membranes deliver long-term UV resistance and durability. Before applying any coating, ensure the surface is thoroughly cleaned, dried, and primed to maximize adhesion. Proper surface prep and choosing the right coating type are essential for weatherproofing your folding roof deck effectively. Incorporating proper surface preparation techniques can significantly extend the lifespan of your waterproofing system.

Drainage and Sealant Use

Effective drainage and sealant use are essential to keep your folding roof deck weatherproof and prevent water damage. Proper design ensures water flows away efficiently, avoiding pooling or leaks. Here’s what you should focus on:

- Incorporate slight slopes (1-2%) on the deck and add integrated drainage channels or scuppers to direct water to exits. Proper slope installation prevents water pooling, which can lead to leaks and structural damage over time.

- Install downspouts or mini-gutters beneath membranes to divert water away from structural parts.

- Seal joints, hinges, and seams with flexible, UV-resistant sealants like silicone or polyurethane, ensuring they accommodate movement and folding.

Choose durable waterproof membranes like EPDM, vinyl, or liquid-applied options, and always follow manufacturer guidelines. Regular inspection and maintenance keep your roof deck protected from water infiltration.

Building Code Compliance and Safety Standards

Ensuring your tiny house roof deck meets building code compliance and safety standards is essential before construction begins. You must comply with local building codes and zoning laws to ensure legality and safety. Roof decks over 30 inches above ground typically require guardrails that meet specific height and strength standards, which vary by municipality. The International Residential Code (IRC) covers structural integrity, guardrails, and emergency escape openings relevant to roof decks. If your tiny house is on wheels, it’s usually classified as an RV and subject to different standards like RVIA certification. Structural design must withstand live and environmental loads, with weather-resistant materials and secure attachment points. Safety features, such as non-slip surfaces and reliable guardrails, are mandatory, along with unobstructed egress for emergencies. Building codes specify load requirements and safety measures for roof decks, ensuring they are safe for occupants and compliant with regulations.

Addressing Engineering Challenges in Fold-Down Mechanisms

Addressing engineering challenges in fold-down mechanisms requires careful selection of hinge and pivot components to guarantee smooth operation without binding or interference. You need to choose hinges that allow a gentle outward push during folding, preventing scraping against the house facade. Using multiple heavy-duty hinges (like seven) distributes the load evenly, boosting durability during repeated use. Verify hinges are attached to a sturdy ledger board designed to withstand fold-down stresses. Additionally, consider weight and balance distribution to avoid undue stress points. Proper hinge placement is crucial for achieving a balanced and safe fold-down system. Key points include:

Ensure smooth, durable fold-down hinges mounted on a strong ledger for reliable roof deck operation.

- Selecting hinges that facilitate smooth folding and prevent binding.

- Incorporating multiple hinges for load sharing and durability.

- Attaching hinges to a robust ledger board to handle stresses.

Focusing on these aspects helps you overcome common engineering hurdles, ensuring safe, reliable fold-down roof decks.

Design Approaches for Foldable Railings and Deck Access

How can you design foldable railings and deck access systems that balance convenience with safety? Start with retractable cable railings that hide when not in use, providing clear views, or pivoting railings for flexible access. Fold-down or hinged railings ensure easy folding while maintaining safety and code compliance. Material choice is key; redwood or pine offers durability and natural aesthetics. For deck access, hinged frames and modular designs allow quick folding or disassembly, while recessed systems keep the deck flush when stowed. Temporary support structures and slide-in mechanisms enhance stability during transport. Minimalist framing reduces weight, and integrating the design with the house’s architecture improves aesthetics. Prioritize safety by using heavy-duty hinges, secure fasteners, and conducting load tests to ensure structural integrity.

Resources and Planning for Custom Engineering Solutions

To develop effective custom engineering solutions for foldable roof decks, you need to collaborate with experienced teams and specialists who understand the unique demands of tiny house structures. First, engage global engineering firms with expertise in complex structural and access solutions, ensuring your design meets safety and regulatory standards. Second, work with architects and designers focused on lightweight, durable materials optimized for weight distribution and weather resistance. Third, utilize custom consultation services to develop innovative foldable mechanisms tailored to your climate and load requirements. These resources help create precise, construction-ready plans. You’ll also benefit from modular fabrication techniques, advanced modeling, and exhaustive project management, ensuring your roof deck is both functional and compliant, ready for seamless integration into your tiny house.

Frequently Asked Questions

How Do Fold-Down Roof Decks Impact Overall Tiny House Weight Limits?

You need to consider how fold-down roof decks add weight to your tiny house. They can push the total trailer weight close to or beyond your vehicle’s limits if not designed carefully. Using lightweight materials, supported hinges, and removable legs helps minimize extra weight. Keep in mind, increased weight affects mobility, safety, and legal road limits, so optimizing your deck’s design is essential to stay within your tiny house’s weight capacity.

What Are the Best Materials for Balancing Durability and Ease of Disassembly?

You might think durable materials are tough to disassemble, but lightweight options prove otherwise. Composite decking offers weather resistance and easy removal with concealed fasteners, while cedar or redwood provide rot resistance and can be easily detached with bolts and locknuts. Steel frames welded for strength ensure stability yet are simple to dismantle with self-tapping screws. Balancing durability and ease of disassembly, these materials make your tiny house safer, lighter, and more flexible.

How Do Local Restrictions Affect Fold-Down Roof Deck Design Options?

Local restrictions directly impact your fold-down roof deck design by dictating size, height, and safety features. You must verify your plans meet local building codes and zoning laws, which may limit deck dimensions or require specific supports and egress routes. Permits and inspections are essential steps, and you might need to adapt your design to address setback rules, noise ordinances, and transportation regulations to keep your tiny house compliant and road-legal.

What Safety Features Are Recommended for Foldable Railings During Transportation?

You should prioritize safety features that protect during transportation. Use foldable railings with locking pins and secure mounting bases to prevent shifting or accidental collapse. Verify they have smooth surfaces to avoid injury and incorporate bright, visible coatings for safety during loading and unloading. Heavy-duty materials like galvanized finishes and rubber pads on bases enhance durability and stability. These features help secure the railings, reduce risks, and ensure safe handling during transport.

How Can I Ensure Long-Term Waterproofing With a Fold-Down Roof System?

Ever wondered how to keep your fold-down roof waterproof for years? You should select high-performance membranes like Protecto Deck™ with fabric coatings for strong adhesion. Use UV-resistant membranes and seal all seams with specialized tapes that self-seal around fasteners. Regularly inspect and maintain seals, especially at hinges and seams, to prevent leaks. Choosing flexible, durable materials and ensuring proper drainage also help extend your roof’s waterproof life.

Conclusion

By carefully planning each engineering detail, you’ll build a folding roof deck that’s both sturdy and easy to use. Pay attention to support, materials, and safety standards, and remember that every challenge is just another brick in the wall to overcome. With the right approach, your tiny house will stand tall and proud, proving that sometimes, it’s the little things that make a big difference. Keep your eye on the prize and enjoy the journey!

I’m Theodore, and I love tiny houses. In fact, I’m the author of Tiny House 43, a book about tiny houses that are also tree houses. I think they’re magical places where imaginations can run wild and adventures are just waiting to happen.

While tree houses are often associated with childhood, they can be the perfect adult retreat. They offer a cozy space to relax and unwind, surrounded by nature. And since they’re typically built on stilts or raised platforms, they offer stunning views that traditional homes simply can’t match.

If you’re looking for a unique and romantic getaway, a tree house tiny house might just be the perfect option.