If you’re searching for the best hydrogen-compatible PTFE tubing, I recommend considering options like high-quality, chemical-resistant, and high-temperature tubing designed for safety and durability. From transparent tubes for filament monitoring to versatile 2.5mm ID options for precise applications, I’ve found several top choices tailored for hydrogen use. Each offers excellent resistance to chemicals and pressure, ensuring safety and long-lasting performance. Stay tuned to discover the detailed features of these reliable tubing options.

Key Takeaways

- High-quality PTFE tubing offers excellent chemical resistance, high-temperature durability, and low permeability, ensuring safe hydrogen transfer.

- Compatibility with various 3D printers and systems makes these PTFE options versatile for hydrogen-related applications.

- Certifications and standards compliance (ISO, ASTM, ASME) ensure safety, structural integrity, and minimal risk of leaks or embrittlement.

- Features smooth interior surfaces and leak-proof fittings to maintain consistent flow and prevent system failures.

- Durability and resistance to wear, abrasion, and deformation support long-term, reliable hydrogen-compatible operation.

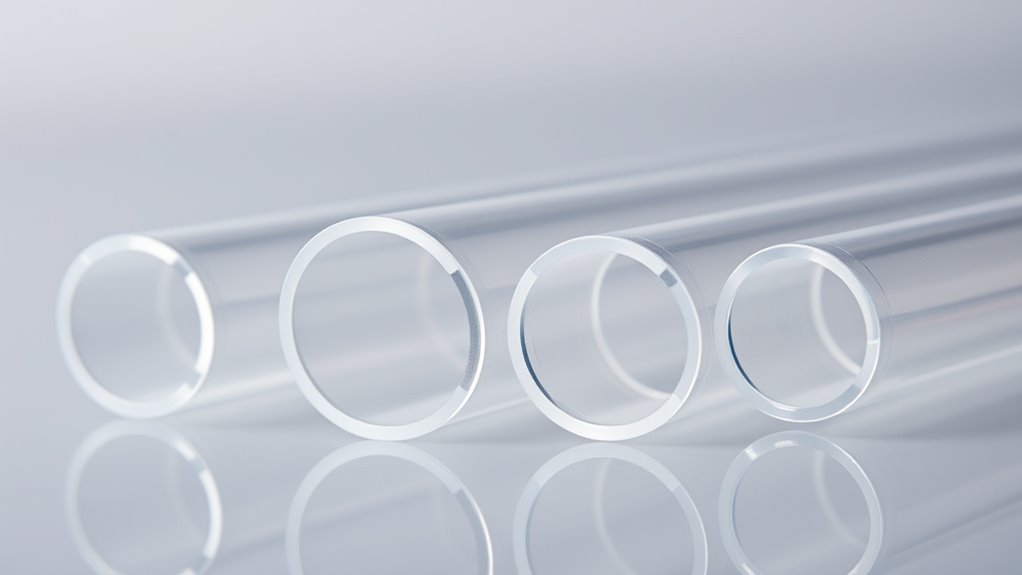

Ultra-Clear PTFE Tube for 1.75mm Filament with Cutter for 3D Printer

Are you looking for a clear, reliable tubing solution for your 3D printer that offers precise filament control? I recommend the Ultra-Clear PTFE Tube for 1.75mm filament, which features a transparent design and a smooth interior for easy filament observation. With a length of 5 meters, it can be cut to fit your specific printer setup. Made of high-quality PTFE, it supports high-speed printing and resists corrosion, handling temperatures up to 260°C. Compatible with multiple printers like Bambu Lab and Creality, it ensures smooth filament flow for PLA, ABS, and PETG, though not ideal for flexible filaments.

Best For: 3D printing enthusiasts and professionals seeking a clear, durable tubing solution for precise filament control across various filament types and printer models.

Pros:

- Transparent design allows easy filament monitoring to reduce printing errors

- High-quality PTFE material offers excellent durability and corrosion resistance

- Supports high-speed printing with low friction, ensuring smooth filament feeding

Cons:

- Not suitable for flexible filaments like TPU/TPE that require larger inner diameters

- Installation requires careful handling due to its stiffness and tendency for sharp bends

- Not compatible with top-mounted AMS units; proper leveling is essential for optimal performance

LUFOX PTFE Teflon Tubing for 3D Printers

LUFOX PTFE Teflon Tubing is an excellent choice for 3D printer enthusiasts seeking reliable, high-quality filament guidance. Its 5-meter length and compatibility with popular models like Bambu Lab A1, Creality K1 series, Ender 3 V3, and K1 Max make it versatile. The tubing’s 2.5mm inner diameter enhances filament flow, improving print quality. Made from durable, high-temperature resistant PTFE, it features a smooth surface for low friction and long-lasting performance. The translucent milky white appearance allows me to observe filament movement easily. Plus, it comes with a cutter for simple installation and adjustments. It’s a dependable option for any 3D printing setup.

Best For: 3D printing enthusiasts and professionals seeking durable, high-quality PTFE tubing compatible with popular direct drive extruder models.

Pros:

- Made from high-temperature resistant PTFE for long-lasting performance

- Inner diameter of 2.5mm improves filament flow and print quality

- Translucent milky white appearance allows easy observation of filament movement

Cons:

- Only available in a 5-meter length, which may be excessive for small projects

- Compatible mainly with specific 3D printer models, limiting versatility

- Requires cutting to desired length, which may be challenging for beginners

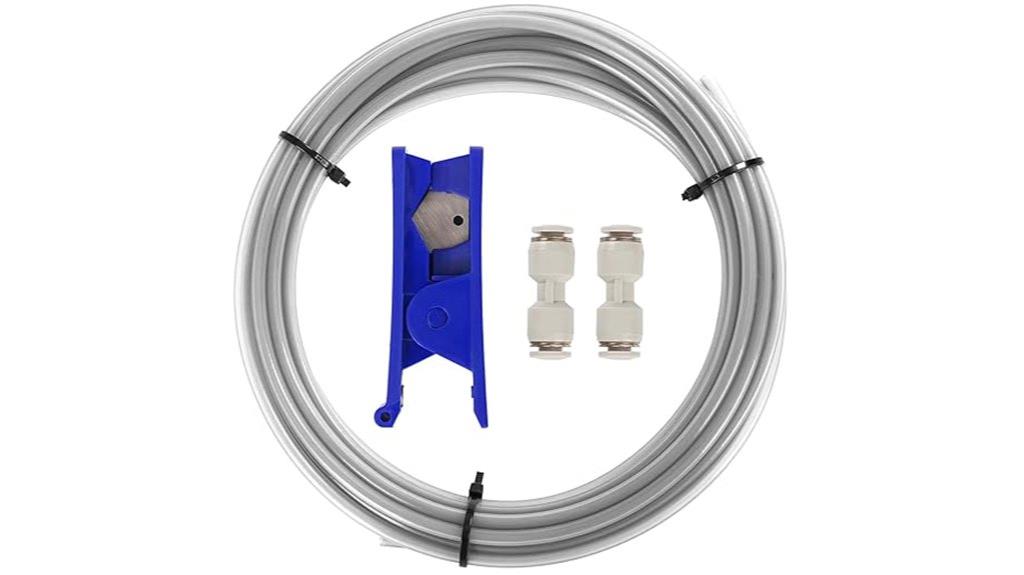

Compatible Bambu-Lab PTFE Tube 2.5mm ID×4mm OD, 5M/16.4ft, for 3D Printers

If you’re upgrading or maintaining a 3D printer that demands smooth filament transfer and high reliability, the Compatible Bambu-Lab PTFE Tube 2.5mm ID×4mm OD is an excellent choice. Made from high-quality, heat-resistant PTFE, it offers durability, low friction, and corrosion resistance, ensuring consistent filament flow. Its milky white, smooth surface minimizes drag, especially with flexible filaments like TPU and TPE. The 5-meter length provides ample tubing for multiple setups or replacements, and the included cutter makes installation easy. Overall, this tubing enhances print quality by reducing jams and maintaining precise filament feeding across various 3D printer models.

Best For: DIY 3D printing enthusiasts and professionals seeking durable, high-quality PTFE tubing for reliable filament transfer and maintenance across various 3D printer models.

Pros:

- Made from high-quality, heat-resistant PTFE for durability and low friction

- Smooth, milky white surface reduces filament drag, ideal for flexible filaments like TPU and TPE

- Includes a cutter for clean, easy installation and maintenance

Cons:

- 5-meter length may be more than needed for single setups, potentially leading to waste for some users

- Compatibility limited to certain printer models, requiring verification before use

- Slightly higher cost compared to generic tubing options

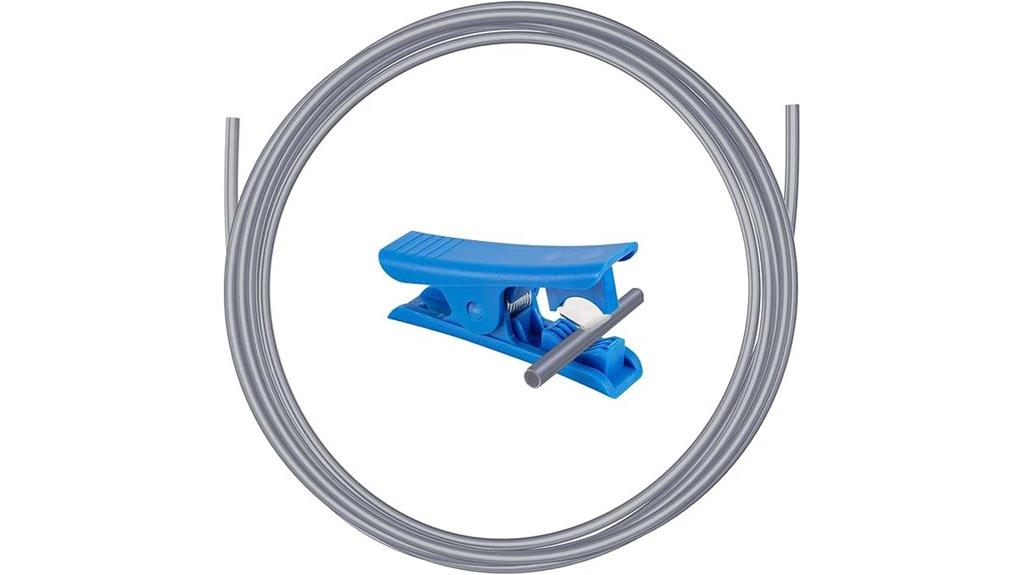

Translucent Gray PTFE Tube Kit, 2.5mm ID×4mm OD, 5M/16.4ft, Compatible with 3D Printers

The Translucent Gray PTFE Tube Kit is an excellent choice for 3D printing enthusiasts seeking durable, high-temperature tubing that guarantees smooth filament flow. Made from high-quality PTFE, it resists heat and chemical exposure, ensuring reliable performance across various printers like Ender 3 V3 and Prusa MMU3. The kit includes a 5-meter length of flexible tubing, a sharp cutter, and four pneumatic fittings for secure connections. Its smooth interior minimizes friction, promoting consistent filament feeding. Easy to install and maintain, this kit enhances print quality and upgrade flexibility, making it a versatile solution for both replacements and custom extensions in diverse 3D printing setups.

Best For: 3D printing enthusiasts and professionals seeking durable, high-temperature tubing for reliable filament feed and easy upgrades or replacements.

Pros:

- Made from high-quality PTFE with excellent heat and chemical resistance

- Includes a sharp cutter and secure pneumatic fittings for easy installation and maintenance

- Flexible, smooth interior promotes consistent filament flow and minimizes friction

Cons:

- The cutter’s speed may require cautious handling to prevent injuries

- 7.8-inch tubing segments may need additional extensions for larger setups

- Compatibility limited to certain printer models, requiring verification before purchase

5 Meters PTFE Teflon Tubing with Tube Cutter

Looking for a reliable solution to precisely cut PTFE Teflon tubing for your 3D printer setup? I recommend the 5-meter PTFE Teflon tubing bundled with a tube cutter. Made from high-quality PTFE, it handles temperatures from -200°C to 260°C, making it perfect for high-temperature filaments. Its smooth interior reduces friction, ensuring consistent filament flow and preventing jams. The included tube cutter allows for clean, accurate cuts, maintaining ideal fit and performance. Compatible with 1.75mm filament types like ABS, PETG, and Nylon, this kit simplifies maintenance and helps keep your prints flawless and reliable.

Best For: 3D printer enthusiasts and professionals seeking high-quality PTFE tubing and precise cutting tools for reliable filament management.

Pros:

- Made from high-quality PTFE capable of withstanding temperatures from -200°C to 260°C for versatile filament use

- Smooth interior reduces friction, ensuring consistent filament flow and minimizing jams

- Includes a tube cutter for clean, accurate cuts, maintaining optimal fit and performance

Cons:

- Regular replacement of PTFE tubing may be necessary to sustain optimal print quality

- The 5-meter length may be excessive for users with minimal printing needs

- Compatibility limited to 1.75mm filament types, requiring different sizes for other filament diameters

Translucent Gray PTFE Tube Kit, 2.5mm ID×4mm OD, 5M/16.4ft, Compatible with 3D Printers

Designed for 3D printing enthusiasts seeking reliable filament guidance, the Translucent Gray PTFE Tube Kit offers high-temperature resistance and smooth flexibility essential for consistent print quality. Made from high-quality PTFE, it includes 2.5mm ID×4mm OD tubing, a cutter, and four pneumatic fittings, supporting various compatible printers like Ender 3 V3, Prusa MMU3, and K2 Plus. The 5-meter length ensures ample extendability, while the fittings guarantee leak-free connections. Its easy-to-install, flexible tubing improves filament flow, reduces jams, and enhances overall print reliability. Perfect for upgrades or replacements, this kit helps maintain excellent print conditions in diverse 3D printing setups.

Best For: 3D printing enthusiasts and professionals seeking durable, high-performance PTFE tubing for reliable filament feeding and printer upgrades.

Pros:

- Made from high-quality PTFE with excellent high-temperature resistance and flexibility

- Includes a cutter and four pneumatic fittings for easy installation and leak-free connections

- 5-meter length provides ample extendability for various setups and customizations

Cons:

- The cutter’s snappy action requires careful handling to avoid injury

- Only compatible with specific 3D printer models listed, limiting universal use

- Slightly higher cost compared to basic tubing options without fittings or cutter

Sovol PTFE Tube 2.5mm ID 4mm OD for 3D Printers

If you need reliable PTFE tubing for high-temperature 3D printing applications, Sovol’s 2.5mm ID 4mm OD tube is an excellent choice. It comes in a 5-meter length, made from high-quality PTFE, providing durability and corrosion resistance. Its precise 2.5mm inner diameter ensures smooth filament flow and reduces jams, especially with flexible filaments like TPU. Compatible with popular printers such as Ender 3 V3, Creality K1 Max, and Sovol models, it handles temperatures up to 340°C. Easy to install, it improves extrusion, minimizes friction, and resists wear over time. Overall, it’s a trusted upgrade for consistent, high-quality 3D printing performance.

Best For: 3D printer users seeking durable, high-temperature PTFE tubing to ensure smooth filament flow and reduce jams in Bowden or direct drive setups.

Pros:

- Made from high-quality PTFE with excellent heat resistance up to 340°C.

- Precise 2.5mm inner diameter minimizes filament drag and jams.

- Easy to install with included accessories, enhancing print quality and reliability.

Cons:

- Slight initial resistance when fitting into connectors, which may require a break-in period.

- The sharp cutter requires careful handling to avoid injury during installation.

- Not suitable for all-metal hot ends designed specifically for nylon or very high-temperature filaments.

HANGLIFE PTFE Tube for 3D Printers, 2.5mm ID × 4mm OD, 16.4ft with Cutter

For 3D printer enthusiasts seeking reliable filament guidance, the HANGLIFE PTFE Tube offers a standout solution with its smooth, high-temperature-resistant construction. Made from premium PTFE, it guarantees reliable filament flow and reduces clogs, supporting print quality. Its ability to withstand temperatures up to 260°C makes it durable across various filament types. The 16.4-foot length allows for flexible customization and multi-printer setups, while the included cutter ensures clean, precise cuts. Though flexible, some users find it slightly floppy, but overall, it’s praised for durability, ease of use, and compatibility with popular 3D printers like Creality and Bambu Lab.

Best For: hobbyists and professionals seeking a reliable, high-temperature-resistant PTFE tube for 3D printers with direct drive extrusion systems using 1.75mm filament.

Pros:

- Made from premium PTFE ensuring smooth filament flow and reducing clogs

- Supports high temperatures up to 260°C, suitable for various filament types

- Includes a high-quality cutter for precise, clean cuts and easy installation

Cons:

- Slightly floppy design may pose challenges in certain setups

- Extended length might require custom trimming for specific applications

- Premium price point could be a consideration for budget-conscious users

MUYI 10 Meters PTFE Teflon Tube (OD 4mm, ID 2mm)

The MUYI 10 Meters PTFE Teflon Tube with an outer diameter of 4mm and an inner diameter of 2mm is an excellent choice for those working with hydrogen-related applications, thanks to its exceptional chemical resistance and high-temperature tolerance. Made from high-quality PTFE, it withstands temperatures from -190℃ to +280℃, ensuring safety and durability in demanding environments. Its smooth interior provides minimal filament drag and clogging, making it ideal for chemical and electrical wiring, including 3D printer extruder pathways. Each 10-meter coil arrives clean, ready for installation, with excellent flexibility and reliable performance, making it a versatile and dependable option for safe hydrogen handling.

Best For: individuals and professionals working with chemical, electrical, or hydrogen-related applications requiring durable, high-temperature resistant tubing.

Pros:

- Excellent chemical resistance and high-temperature tolerance from -190℃ to +280℃

- Smooth interior minimizes filament drag and clogging, ideal for 3D printer extruders

- Flexible and easy to install, arriving clean and ready for immediate use

Cons:

- Packaging may sometimes be prone to bends or less secure winding

- Only available in a 10-meter length, which may be excessive for small projects

- Limited color options, primarily white, which might not suit all aesthetic preferences

16.4ft PTFE Teflon Tube Kit for 3D Printers

Designed specifically for 3D printers with 1.75mm filament Bowden systems, the 4ft PTFE Teflon Tube Kit offers a dependable solution for smooth filament feeding. It includes tubing, connectors, and a cutter, allowing quick setup and immediate printing. Made from high-temperature resistant PTFE, it withstands -200°C to 260°C, resisting abrasion and deformation. Its smooth internal surface ensures low friction, reducing clogging and maintaining consistent filament flow. The kit’s connectors provide secure, quick attachment to extruder and hotend. Whether upgrading or customizing, this kit ensures reliable performance, making your 3D printing experience smoother and more efficient.

Best For: 3D printer users seeking a high-quality, high-temperature resistant PTFE tubing kit for reliable filament feeding and easy customization.

Pros:

- Durable and resistant to abrasion, cracking, and deformation under pressure

- Smooth internal surface ensures low friction and reduces clogging

- Compatible with a wide range of printers and filament types, including TPU and TPE

Cons:

- Installation may require checking compatibility with specific printer models

- Kit length (4ft) might require customization for larger setups

- Connectors and cutter may need careful handling to ensure secure fit and clean cuts

HANGLIFE PTFE Tube for 3D Printers (2.5mm ID × 4mm OD, 16.4ft)

If you’re seeking reliable PTFE tubing for precise filament feeding in your 3D printer, the HANGLIFE PTFE Tube offers an excellent solution. Designed for direct drive systems with 1.75mm filament, it’s compatible with models like Bambu Lab A1 Mini, Creality Ender 3 V3, and others. Made from high-quality PTFE, it guarantees smooth filament flow, reduces clogs, and withstands temperatures up to 260°C. Its 16.4-foot length allows flexible customization for multiple printers or projects. The included cutter makes installation easy, and users praise its durability and ease of use. While flexible, some find its floppiness challenging in certain setups, but overall, it’s a durable, versatile choice.

Best For: hobbyists and professionals seeking reliable, high-quality PTFE tubing for precise filament feeding in direct drive 3D printers using 1.75mm filament.

Pros:

- Ensures smooth filament flow and reduces clogs for improved print quality

- Made from durable, high-temperature resistant PTFE material up to 260°C

- Includes a high-quality cutter for easy and precise installation

Cons:

- Excessive floppiness may pose challenges in certain setups

- Longer length may require cutting and handling for specific configurations

- Some users might find the flexible tubing less supportive in tight or complex installations

USA Sealing Teflon PTFE Tubing (ZUSA-HT-1606, 1/4ID, 3/8OD, 2ft)

USA Sealing’s Teflon PTFE tubing (ZUSA-HT-1606) stands out as an ideal choice for applications demanding high chemical and heat resistance, especially in hydrogen-related systems. Its 1/4-inch ID and 3/8-inch OD dimensions make it perfect for precise, leak-free connections. Made from food-grade, isoalkane-cured PTFE, it offers superior chemical resistance and excellent heat tolerance, including steam sterilization. Its flexibility without reinforcement simplifies installation in demanding industrial and food-grade environments. With a hard 45D+ grade, this tubing ensures durability and reliability in critical applications, making it a trustworthy option for safe and long-lasting hydrogen-compatible systems.

Best For: Industries and applications requiring high chemical and heat resistance, especially in chemical handling, sterilization, and hydrogen-related systems.

Pros:

- Superior chemical resistance suitable for demanding environments

- Excellent heat tolerance, including steam sterilization capability

- Flexible, food-grade PTFE tubing without reinforcement for easy installation

Cons:

- No reinforcement may limit mechanical strength in certain applications

- Slightly higher cost compared to standard tubing materials

- Limited flexibility at very low temperatures due to hardness (45D+)

PTFE Teflon Tubing 16.5ft with Cutter for 3D Printer

For 3D printer enthusiasts seeking reliable filament guidance, the PTFE Teflon Tubing 16.5ft with Cutter is an excellent choice. Designed for 3mm filament Bowden setups, it offers a 4mm ID x 6mm OD, compatible with popular models like Creality Ender 3 and Prusa i3 MK3. Made from high-quality PTFE, it guarantees smooth filament feeding with reduced clogging risk, even at high temperatures. The included cutter allows for precise length adjustments, and the tubing’s durability supports consistent performance over time. Its chemical resistance and FDA compliance make it versatile and safe, perfect for both hobbyist and professional 3D printing applications.

Best For: 3D printing enthusiasts and professionals using 3mm filament Bowden setups who need durable, high-quality PTFE tubing for smooth filament feeding.

Pros:

- Provides smooth filament guidance with reduced clogging risk, even at high temperatures

- Made from high-quality, FDA-compliant PTFE material that is resistant to chemicals and wear

- Includes a cutter for easy customization of tube length, ensuring precise installation

Cons:

- Only compatible with 3mm filament printers; not suitable for 1.75mm filament setups

- Requires printing tube guides for a clean, flat cut, adding an extra step in installation

- May be overkill for simple or low-temperature 3D printing projects where standard tubing suffices

YOOPAI PTFE Teflon Tube 5M with Cutter for 3D Printers

The YOOPAI PTFE Teflon Tube 5M with Cutter is an ideal choice for 3D printer enthusiasts seeking reliable, high-quality tubing compatible with a wide range of direct-drive extruders. Its high-grade PTFE resin guarantees durability, corrosion resistance, and long-lasting performance. The ultra-smooth, oil-free surface reduces friction, promoting stable filament feeding with an inner diameter of 2.5mm. It withstands temperatures up to 260°C, suitable for printing various filaments like PLA, ABS, and TPU. The package includes a cutter for easy installation and adjustments. Regular inspection and timely replacement help maintain peak performance, making this tubing a versatile, safe option for demanding printing needs.

Best For: 3D printing enthusiasts and professionals seeking durable, smooth, and temperature-resistant PTFE tubing compatible with a variety of direct-drive extruder printers.

Pros:

- High-quality PTFE resin ensures durability, corrosion, and oxidation resistance.

- Ultra-smooth, oil-free surface reduces filament friction for stable feeding.

- Compatible with a wide range of 3D printers and withstands temperatures up to 260°C.

Cons:

- PTFE tubes are consumables that require regular inspection and replacement due to wear.

- Inner diameter of 2.5mm may not suit all filament types or extruder configurations.

- May need additional tools or adjustments for installation on certain printer models.

Factors to Consider When Choosing Hydrogen Compatible Tubing PTFE

When selecting PTFE tubing for hydrogen applications, I focus on key factors like purity, material grade, and temperature and pressure ratings to guarantee safety and performance. Compatibility with hydrogen, chemical resistance, and durability are also vital to withstand demanding conditions. Additionally, I consider flexibility and size options to fit my system’s specific needs efficiently.

Purity and Material Grade

Choosing the right PTFE tubing for hydrogen applications hinges on its purity and material grade, as these factors directly influence safety and performance. High purity, typically food-grade or medical-grade, guarantees minimal contamination, which is vital for safe hydrogen transfer. PTFE with 99.9% or higher purity offers excellent resistance to hydrogen embrittlement and reduces reactive impurities. Manufacturing processes that meet strict standards eliminate residual solvents, moisture, and contaminants, maintaining hydrogen purity throughout the system. Additionally, the grade of PTFE affects thermal stability and mechanical strength, with premium grades withstanding high pressures and temperatures common in hydrogen systems. Confirming the tubing has certified material composition and traceability not only guarantees compliance with safety standards but also markedly reduces the risk of impurities compromising system integrity.

Temperature and Pressure Ratings

Ensuring PTFE tubing can handle the high pressures and temperatures encountered in hydrogen systems is vital for safety and reliability. Hydrogen-compatible PTFE tubing typically withstands pressures up to 3,000 psi or more, preventing leaks or failures under demanding conditions. Its temperature ratings range from -200°C to +260°C, covering the extreme cold and heat often present in hydrogen storage and transfer. PTFE’s excellent chemical resistance helps maintain integrity even at elevated temperatures and pressures, guaranteeing consistent performance. When selecting tubing, it’s important to verify that its specified pressure and temperature ratings meet or exceed your system’s operating conditions. Doing so minimizes risks, enhances safety, and ensures long-term durability, making the right ratings a key factor in your choice of hydrogen-compatible PTFE tubing.

Compatibility With Hydrogen

Selecting PTFE tubing that’s truly compatible with hydrogen involves more than just matching pressure and temperature ratings; it requires careful consideration of material properties and industry standards. Hydrogen’s high-pressure environments demand tubing that can withstand these conditions without permeating or leaking, ensuring safety during transport. The tubing must also resist hydrogen embrittlement, preventing degradation over time in hydrogen-rich atmospheres. PTFE’s low permeability to gases makes it suitable for hydrogen, minimizing gas leakage risks. Additionally, the material should handle operating temperatures up to 260°C without deforming or losing integrity. Finally, meeting industry standards for purity and safety is essential; the tubing must be free from contaminants that could react with or weaken hydrogen, guaranteeing both safety and performance in critical applications.

Chemical Resistance and Durability

When it comes to hydrogen-compatible PTFE tubing, chemical resistance and durability are essential factors that directly impact system reliability. PTFE’s ability to withstand aggressive chemicals like acids, bases, and solvents ensures it remains intact even in harsh environments. Its high durability allows it to perform consistently over time, resisting cracking, deformation, and wear that could cause leaks or failures. This resilience is vital for maintaining safety and efficiency in hydrogen systems. Additionally, PTFE maintains its integrity across a broad temperature range from -200°C to 260°C, enabling reliable operation in diverse conditions. Properly rated PTFE tubing also prevents hydrogen permeation, safeguarding the system’s integrity over extended use. Overall, these qualities make PTFE an excellent choice for long-term, safe hydrogen applications.

Flexibility and Size Options

Hydrogen-compatible PTFE tubing is designed to offer high flexibility, making it easier to install in complex piping layouts and reducing stress on connections. This flexibility is vital for adapting to tight spaces and guaranteeing smooth bends without kinking. Inner diameters typically range from 1/8 inch to 1/4 inch, allowing you to select based on flow rate needs. Thinner wall thicknesses increase flexibility but can lower pressure resistance, so choosing the right size depends on your system’s pressure requirements. Larger sizes, like 1/4 inch ID, provide lower resistance and higher flow capacity, ideal for high-volume hydrogen transfer. Matching diameter and wall thickness with fittings is essential to ensure compatibility, ideal flow, and safety in hydrogen applications.

Safety and Certification Standards

Ensuring safety and compliance is essential when choosing PTFE tubing for hydrogen applications, as strict standards govern its performance and reliability. These standards, like ISO 15512 and ASTM D3291, ensure the tubing offers excellent chemical resistance and structural integrity. Certification for hydrogen service often requires adherence to industry-specific standards such as ISO 1988 or ASME B31.3, confirming the tubing can withstand high pressures and temperatures safely. It’s also imperative that the tubing has certifications indicating resistance to permeation and off-gassing, helping prevent leaks and hazards. Regulatory requirements may demand traceability and quality assurance documentation, including material origin, testing reports, and compliance certificates. Meeting these safety and certification standards is critical to prevent failures that could lead to leaks, explosions, or health risks in sensitive environments.

Ease of Installation

Choosing PTFE tubing that’s easy to install can substantially streamline setup and maintenance in hydrogen systems. The smooth internal surfaces minimize resistance and reduce leaks during installation, making connections more secure and straightforward. Its flexibility and ample length allow for easier routing through complex setups, saving time and effort. Compatibility with standard fittings and connectors means you don’t need specialized tools, simplifying attachment and ensuring leak-proof seals. Clear or translucent tubing provides visual access to the flow path, enabling quick inspection, adjustments, and troubleshooting without disassembly. Additionally, PTFE’s high-temperature and chemical resistance ensure durability and ease of handling in demanding environments. Overall, selecting tubing designed for easy installation enhances safety, efficiency, and reliability in hydrogen applications.

Frequently Asked Questions

How Does Temperature Affect PTFE Tubing’s Hydrogen Compatibility?

Temperature critically impacts PTFE tubing’s hydrogen compatibility. As temperature rises, PTFE becomes more flexible but can also degrade faster if exposed to extreme heat, potentially affecting its integrity. At higher temperatures, hydrogen molecules may diffuse more quickly through the material, so maintaining the recommended temperature range is vital. I always make certain my PTFE tubing operates within specified limits to keep it safe and reliable for hydrogen use.

What Are the Best PTFE Materials for High-Pressure Hydrogen Systems?

For high-pressure hydrogen systems, I recommend using virgin PTFE materials with high purity levels, as they offer excellent chemical resistance and minimal gas permeability. Look for products specifically rated for high-pressure applications, ensuring they meet industry standards like ASTM D3292. I also suggest choosing PTFE tubing with reinforced layers or thicker walls for added strength and safety. Always verify compatibility and pressure ratings before installation.

How Do Different PTFE Tube Dimensions Impact Hydrogen Safety?

Different PTFE tube dimensions markedly impact hydrogen safety by influencing pressure handling and leak prevention. Thicker walls provide greater durability and resistance to hydrogen embrittlement, reducing rupture risks. Smaller diameters can improve control and minimize gas volume, but may require higher pressure ratings. I always guarantee the tubing’s dimensions match system specifications, balancing safety and efficiency. Proper sizing is essential for maintaining safe, reliable hydrogen operations.

Are There Specific Certifications for Hydrogen-Compatible PTFE Tubing?

Yes, there are specific certifications for hydrogen-compatible PTFE tubing. I look for tubing with certifications like ISO 11114-3 and DOT standards, which guarantee the material’s safety and compatibility with hydrogen. These certifications verify the tubing’s ability to handle hydrogen’s unique properties safely. Always choose tubing that meets these recognized standards to ensure reliable performance and safety in hydrogen applications.

How Does PTFE Tubing Resist Chemical Degradation From Hydrogen Exposure?

Hydrogen’s presence is like a silent storm, but PTFE tubing stands firm against it. I’ve found that PTFE resists chemical degradation from hydrogen because of its exceptional chemical inertness and tight polymer structure, which prevents hydrogen from penetrating or reacting. This resilience guarantees the tubing maintains its integrity, even in demanding environments, making it a reliable choice for safe, long-term hydrogen use without worry about corrosion or material breakdown.

Conclusion

Choosing the right PTFE tubing is like selecting a trusted guardian for your journey into hydrogen safety. Each option acts as a sturdy bridge, ensuring your flow remains smooth and secure. By considering compatibility and quality, you’re forging a path that leads to reliable, leak-free operation. Think of these tubes as the silent guardians—standing firm and unwavering, guiding your process safely into the future. Trust in their strength, and your mission will always stay on course.